Announced this past May, Scott Keogh would leave his position as CEO of Volkswagen of America to become CEO of a car company inside the Volkswagen Group that didn’t yet exist.

It fell to Keogh to revitalise Volkswagen’s presence and market share in North America by reviving the iconic Scout brand, which the Volkswagen Group inherited when it took over the remaining portion of truck maker Navistar.

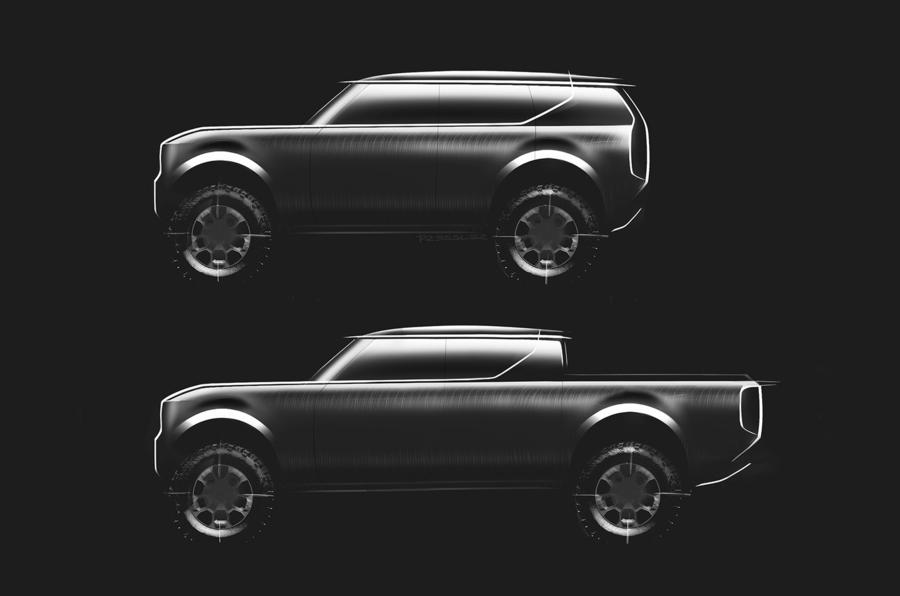

Scout was the model from International Harvester that founded what became the sport utility vehicle category beginning in 1962. By 1966, Ford brought out the Bronco SUV, with rival Chevrolet launching the Blazer in 1969, cementing the category into the American market through competition. Keogh maintained that Scout would be designed and built in North America with an SUV and pickup body on a ladder frame. So, with six people in total, Keogh and company began to look at how Scout could begin producing all-electric vehicles by 2026.

This story is an extract from the January 2023 issue of Auto Forecast Solutions’ monthly report. Auto Forecast Solutions is the only fully integrated solutions provider of vehicle, powertrain, drivetrain and electrification production forecasting, business planning software and advisory services to the global automotive industry.

Much has happened since Scout was outlined in the May 2022 issue of the AutoForecast Monthly Report. Former Volkswagen Group CEO Herbert Diess, under whom Scout was reconstituted, planned for Scout building a dedicated, stand-alone EV factory in North America. Traveling about the country this past summer, Keogh held talks with city leaders in Bloomington, Indiana, where International Harvester built the majority of Scout SUVs. Coincidentally, Audi was also looking to establish additional production capacity in North America and sought to co-locate EV production lines with Scout’s new factory, wherever it would be. While site surveys continued in Bloomington and other locations, Audi’s plan to co-locate with Scout were laid to rest. Diess and the board decided that Scout was to be a solo operation.

That began to change when Diess was ousted by the Volkswagen supervisory board in early August and replaced by Porsche head Oliver Blume on September 2. Along with most of the Volkswagen Group’s initiatives, Scout was reviewed in depth at Wolfsburg and reimagined as an asset-light entity, newly responsible for returning six-digit production and sales figures per year. Taken to its logical conclusion, asset light means that Scout won’t have a dedicated factory. Wishing to maintain the cachet of having Scout designed and built in North America, Volkswagen decided first on having Scout built on contract.

For Keogh and the nascent team at Scout, choosing between North American contract manufacturers Magna and Hon Hai Precision, known colloquially as Foxconn, seemed to go smoothly. Both contract manufacturers have vehicle design and development teams in-house so are capable of designing and assembling the all-electric architecture Scout requires. Foxconn’s Lordstown plant is ready to build Volkswagen’s newest vehicles at 100,000- plus volumes, which was attractive. Talks with Magna that began in October were also productive. The company’s record producing various BMW, Mercedes-Benz and the all-electric Jaguar I-Pace and Fisker Ocean models in Graz, Austria cemented the company’s capabilities with the Volkswagen team. Magna indicated it would use the Volkswagen contract to build the North American assembly facility the company has wanted. In contrast, Foxconn had only started to build Lordstown Motors’ pickup at its facility in Lordstown, Ohio, at the beginning of September.

Volkswagen’s Scout team also considered the bid build prices between the two. Unsurprisingly, Foxconn offered the lowest production costs per vehicle, which were orders of magnitude below Volkswagen’s own vehicle build costs in either Europe or its Chattanooga plant. Volkswagen managers recognised this as Foxconn being willing to do almost anything to get its first, high-volume order from what promises to be a high-profile brand. Magna’s build cost was higher but still represented a value compared with Volkswagen’s.

With competitive bids, costs and recommendations in favour of Foxconn in hand, Keogh and company passed the decision to Volkswagen’s supervisory board in Wolfsburg at the end of October. And that’s when the wheels began to come off of the wagon.

The first signs of dissent about the Scout assembly plan with Foxconn came from a surprising corner. The board members representing the works councils, the actual line employees at Volkswagen, and IG Metall, the largest labor union in Germany, each questioned Foxconn’s ability to build a quality vehicle with so little vehicle assembly experience under its belt. Foxconn’s business model is to add vehicle assembly to its electronics and consumer goods assembly portfolios, not to substitute or replace any of the existing business lines. In contrast, Magna’s entire business model focuses exclusively on the automotive industry. This appealed to the two board members and was a key part of their argument for working with Magna. Additional questions surrounding Foxconn’s low unit production price persisted. Could it really be that low? Would Foxconn’s inexperienced vehicle assembly team cause expensive delays and even long-term quality issues with finished products? The two board members were more comfortable with Magna’s expertise and experience to avoid these issues.

Other questions about Foxconn emerged as the supervisory board’s discussions continued. Uppermost was Foxconn’s recent behaviour during the stringent coronavirus lockdowns at its iPhone factory in Zhengzhou, the capital of Henan Province, China. Workers first fled the factory for fear of being locked in with inadequate food and supplies. Later, the remaining workers rioted when those very conditions came to pass. Would an inexperienced Foxconn management team have enough cultural awareness to exercise the proper discretion with US workers? How would an incident at Foxconn’s Lordstown Plant reflect on Volkswagen?

More pointedly, the board members began asking themselves how the government of the People’s Republic of China might respond to Volkswagen doing business with Taiwan’s Foxconn, in light of Volkswagen’s increased reliance on China to maintain the company’s financial health.

Most concerning, Foxconn’s Hon Hai Tech Day on October 18 introduced the Model B crossover, the Model C SUV and Model V pickup truck as prototypes available to any and all interested OEMs and startups. Foxconn intended the three prototypes to showcase the company’s vertical integration with its own MIH (Made In Harmony) design consortium bringing the entire Contract Design and Manufacturing Service (CDMS) into being. But what alarmed the Volkswagen board was the fact that all three vehicles were completed and reasonably functioning prototypes with distinct bodies, styling and Foxconn logos. In contrast, Magna’s electric skateboard, developed with Israel’s REE Automotive, made its debut in 2021 without a top hat and is currently being supplied to Fisker Inc. as part of Magna’s contract production of the Fisker-designed Ocean SUV in Graz, Austria. The relationship between Magna and Fisker illustrated the supplier-OEM relationship Volkswagen was seeking. Foxconn’s branded and mostly complete EV prototypes indicated to some members of the supervisory board that Foxconn was threatening to become a manufacturer of vehicles in its own right. Was it in Volkswagen’s interest to let a potential future competitor gain experience with volume manufacturing by allowing Foxconn to build Scout? The board meeting broke up, with no decisions made and more follow-up work to be performed. Magna International was extended the opportunity to resubmit its proposal to co-design and produce the Scout SUV and pickup.

All of which gives Audi another opportunity to benefit from Scout’s platform development as well as an incremental increase in volume production in North America.

Audi has long underperformed in North America in comparison with rivals BMW and Mercedes-Benz. A rough and ready SUV or even an Audi pickup would do much to expand the brand’s product line into areas not occupied by Audi’s rivals. If Audi were to produce a ladder-framed, all-electric SUV on contract in the US, it could introduce a direct competitor to Mercedes-Benz’s Geländewagen, a vehicle able to compete in the most rugged terrain there is. Moreover, the Audi EV would be launched as an all electric, all-terrain vehicle, beating the all-electric version of the G-Class to market. Most of all, Audi is already tasked with supporting Magna in the development of Scout’s battery technology and electronic architecture. Under Audi’s guidance, Volkswagen Group modules and sub-assemblies are to be integrated into the new Scout products during the design and build phases of the project. It was not lost on the board that Magna already builds the Geländewagen for Mercedes-Benz in Graz, Austria.

Including an Audi product run of a speculative 50,000 units on top of the 100,000 units of volume expected for Scout would theoretically reduce the per-unit build cost for each of the brands. Having an Audi SUV built in the same facility as Scout would complicate the Volkswagen Group’s relationship with its dealers. As previously reported, Volkswagen dealers’ desire for a pickup truck to sell has been thwarted by the manufacturer’s insistence that Scout is a separate brand.

Adding an Audi SUV to Scout’s production run would undercut that argument. Even so, adding an Audi product to Scout’s production contract is an idea gaining traction in Wolfsburg, and under serious consideration by the board. Audi supports the idea, provided Magna gets the contract. A Foxconn award would be likely to mean Scout would go it alone and provide proof that Foxconn can meet the proper build quality standards.

As things stand, much of the board is predisposed to awarding Magna the contract to build Scout in the US – and, by extension, a new Audi model. But time grows short if Keogh’s promise of a 2026 debut for an all-new, all-electric Scout is to be kept. That would require a decision to be made in January. Can the Volkswagen supervisory board come together that quickly? Audi, along with the rest of us, should soon find out.

Conrad Layson